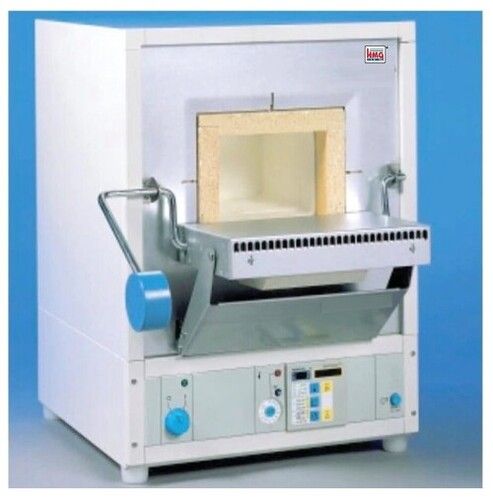

Product Description

A muffle furnace is a special kind of oven used for heating materials to high temperatures, typically ranging from 300C to 1700C. Whats unique about a muffle furnace is that it isolates the material being heated from the fuel and any combustion byproducts like gases or ash. This makes it particularly valuable for applications where:

- Cleanliness is crucial: Muffle furnaces prevent contamination of the material with combustion products, ensuring purity and accurate analysis.

- Controlled atmosphere is needed: Some processes require specific gas environments around the material during heating. Muffle furnaces can be sealed and purged with desired gases for precise control.

- Oxidation needs to be avoided: If a material shouldnt react with oxygen during heating, the sealed environment of a muffle furnace helps prevent oxidation.

Muffle furnaces come in various sizes and capabilities, but they typically share these features:

- Insulated chamber: Thick refractory brick or ceramic insulation surrounds the heating chamber to retain heat and minimize energy loss.

- Heating elements: Electric heating elements are embedded in the chamber walls or muffle (the inner heat shield) to generate controlled heat.

- Temperature control: Temperature controllers, often digital, allow for precise setting and monitoring of the furnace temperature.

- Door: A sealable door provides access to the chamber while minimizing heat loss and preventing contamination.

Muffle furnaces find application in diverse fields like:

- Laboratories: For ashing samples, analyzing materials, and performing heat treatments.

- Ceramics and glassmaking: For firing clay, sintering powders, and melting glass.

- Jewelry making: For annealing, soldering, and brazing metals.

- Electronics: For curing resins and drying components.

- Dentistry: For sterilizing instruments and creating porcelain crowns

Precision Control and Safety FeaturesEquipped with a PID digital temperature controller and LED display, the furnace ensures precise temperature management for demanding laboratory or industrial tasks. Enhanced safety is provided by over-temperature protection and an automatic safety cut-out. The front-opening door, lined with ceramic insulation, minimizes heat loss and operator exposure, promoting both reliable performance and safe operation.

Durability and Efficient PerformanceConstructed with a powder-coated mild steel outer body and a high-grade ceramic inner chamber, this muffle furnace stands up to continuous use. Ceramic fibre insulation provides excellent thermal retention, while Kanthal wire or SiC rod heating elements deliver fast warm-up times, reaching set temperatures in just 1530 minutes. Temperature uniformity of 5C at 1000C ensures consistent experimental results.

Versatile Applications and Comprehensive AccessoriesDesigned for laboratory, industrial, metallurgical, and ceramics applications, the furnace comes complete with a ceramic tray, tongs, and detailed user manual. Its 12 Litre chamber (6x6x12 inch) accommodates a range of sample sizes, making it ideal for material testing, ash content determination, and research. Table-top installation and ISO/CE compliance ensure adaptability and trust for every user.

FAQs of Muffle Furnace:

Q: How is precise temperature control achieved with this muffle furnace?

A: The furnace employs a PID digital temperature controller with an LED display to deliver highly accurate temperature settings and maintain stability throughout operation. This minimizes deviations and maximizes repeatability for sensitive laboratory tasks.

Q: What applications can this muffle furnace be used for?

A: It is suitable for various processes, such as material testing, ash content determination, ceramic or metallurgical research, and other high-temperature laboratory or industrial applications, thanks to its robust design and reliable performance.

Q: When should I use the included safety features?

A: Always engage the safety features, such as over-temperature protection and safety cut-out, when operating at high temperatures or when the unit is unattended. These mechanisms protect both the equipment and user from excessive heat and potential hazards.

Q: Where can this muffle furnace be installed?

A: The furnace is designed for convenient table-top installation, fitting well in laboratory, industrial, and educational environments due to its compact size (6x6x12 inch chamber) and sturdy construction.

Q: What is the recommended process for achieving optimal temperature uniformity?

A: For best results, preheat the furnace according to the user manuals guidelines, ensuring warm-up time of 1530 minutes depending on the targeted temperature. Arrange samples symmetrically on the supplied ceramic tray to maintain uniform heating (5C at 1000C).

Q: How do the materials and build quality benefit daily usage?

A: The high-grade ceramic inner chamber and ceramic fibre insulation offer exceptional heat resistance and energy efficiency, while the powder-coated mild steel outer body ensures durability. These features reduce maintenance needs and enhance service life even under frequent usage.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese